Title:

Thermal and Hygrothermal Services

Provided to the State of Florida and Florida’s Association of Roofing

Professionals to Troubleshoot and Document Field Cases of Attics Sealed with Spray

Foam Insulation

Agency: Oak Ridge National Laboratory (ORNL), One Bethel Valley Road, P.O. Box 2008, Building 3147, MS 6070, Oak Ridge, TN 37831-6070, Contact: Roderick Jackson, Phone: (865) 241-8809, Email: jacksonrk@ornl.gov

Contacts:

Andre Desjarlais, Buildings Technology

Research and Integration Center, Engineering Science & Transportation Division,

One Bethel Valley Road, Building 3147, Oak Ridge, TN 37831-6070, Phone (865) 574-0022, FAX (865)

574-9354,desjarlaisa@ornl.gov

Introduction:

Moisture damage in vented and sealed attics is often the result of poor workmanship allowing the intrusion of bulk water into the structure. A poor job of flashing a roof dormer lets bulk water saturate the wood sheathing, and it is not easily detected if the attic is sealed with spray foam. Also a poorly sealed attic can lead to a risk of condensation of water vapor due to the unwanted air leakage from the outdoors. Water vapor can also enter from the interior as moisture loads rise through occupancy. Developing defensible designs for correcting the effects of air leakage and convection/diffusion of water vapor is the topic of this proposal.

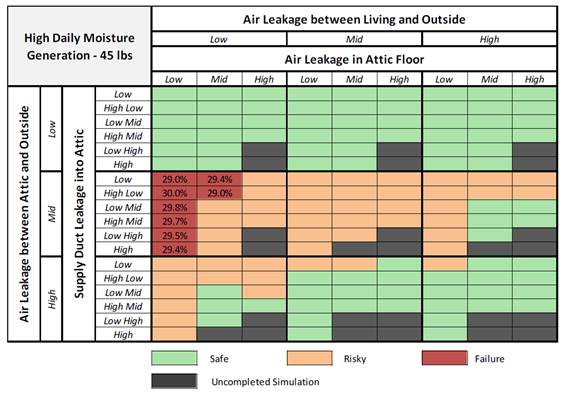

A research team at ORNL investigated the indoor comfort and durability of residential houses with unvented attics in a mixed-humid climate. Building energy and hygrothermal software packages were coupled into a toolkit and used to investigate the impact of 5 independent variables on the moisture durability of the roof sheathing and the comfort of the indoor environment of a home fitted with a sealed attic. The independent variables included the leakage areas of 1) the attic to the outside, 2) the living space to the outside, and 3) the living space to the attic space, as well as 4) the attic duct leakage and 5) the interior moisture generation. Based on these analyses a methodology was formulated for judging the impact of sealed attics on the indoor comfort and the durability of the roof sheathing as affected by the actual leakage area, duct leakage and interior moisture generation in the home. For example, Figure 1 highlights an area with red boxes where the assessment predicted high risk for failure of the roof sheathing due to the diffusion of water vapor. Figure 1 also provides plausible corrective actions.

Opportunity:

The dearth of factual information on the durability of roof sheathing sealed with spray polyurethane foam insulation continues to confound the building community as code officials attempt to legislate practices that will alleviate and not exacerbate structural risk. The ORNL toolkit can help. It predicts the temperature field and concentration field (partial pressure of water vapor) from which moisture drive can be computed to judge the effects of heat and moisture on the durability of the wood structure for ventilated and sealed attics. Few computational tools are equipped or benchmarked that adequately predict the effect of simultaneous heat and mass transfer in attics, and field data is essential. The FRSA continues to receive calls and inquiries from concerned Florida contractors and homeowners about issues involving attic’s sealed with spray foam. Therefore proposal is made to 1) catalogue attics in Florida and document moisture problems voiced by concerned homeowners, 2) benchmark the toolkit against the field data, 3) develop defensible, remedial solutions for the FRSA to offer Florida homeowners for possible deficiencies in sealed attic design.

Project:

The ORNL methodology predicts the risk of moisture damage by vapor diffusion and by the airflow that carries water vapor into the attic from the living space and from the outside. It is proposed to collaborate with the FRSA, the Florida Building Commission and the University of Florida to provide service to the constituents in the state of Florida. ORNL will use a toolkit comprised of EnergyPlus, WUFI® Pro and MathWorks® MATLAB to conduct simulations based on homeowner inputs to a questionnaire and some field measurements. Blower door and duct blaster tests will be conducted on homes to document whole house, attic-to-outside, and living-to-attic air leakage as well as total duct leakage. Portable data loggers will be installed in the attics of candidate homes having moisture problems. The logger will continuously measure air temperature and relative humidity of the living space and the attic air temperature and humidity. The roof sheathing temperature and humidity and roof sheathing moisture content will also be recorded continuously for a full year. About 3 months of data will be collected prior to attic repairs after which the home will be monitored for one year.

Task 1: A key goal of

this study is to survey and document the risk potential (if any) and the

compromise of occupant comfort in Florida homes that are sealed using ocSPF or

ccSPF. The computer toolkit will be exercised

to show homeowners attic deficiencies that require repair. As an example, if a

home’s risk falls in the red box area of Figure 1 then the attic leakage area

to the outside can be reduced to decrease the risk for moisture damage.

Task 2: Acquire field data and develop database of homes with sealed attics having moisture problems.

Report: Document the results of the surveys and

field data. Include the findings of the

computer toolkit and associated recommendations to the FRSA and Commission who, in turn, will provide recommendations

to the Florida homeowners. Provide a lessons learned presentation to

interested participants in Florida.

Cost: Request funds: $100k

Figure 1: Risk Assessment Methodology

for determining failure of the roof sheathing. The roof sheathing’s moisture

content (%) is displayed in the red highlighted cells.