The

following is a proposed code change to incorporate the provisions of Rule

9B-3.0475, Hurricane Mitigation Retrofits for Existing Site-Built Single Family

Residential Structures into the 2007

Revise Chapter 2, Definition, to add a definition for the term “Site Built single – family residential structures” to read as follows:

Site built single- family residential structures. This term shall mean site built single family detached residential structures

Revise Chapter 6, Alteration –Level 1, to add a new section 611.7 to read as follows:

611.7 101.1 When a roof covering on an existing

site-built - single family residential structure is removed and replaced,

the following procedures shall be permitted to be performed by the roofing

contractor:

(a) Roof-decking attachment and fasteners shall be

strengthened and corrected as required by Section 611.7.1 201.1.

(b) A secondary water barrier shall

be provided as required by section 611.7.2 201.2.

Exception: Single family residential structures

permitted subject to the Rule

section.

611.7.1 201.1 Roof decking sheathing

fastening for site-built

single family residential structures. For site-built

single family residential structures the fasteners

and spacing required in Table 201.1 are deemed to comply with the requirements

of Section 507.2.2, of the 2004

Fastening shall be in accordance with

section 611.7.1.1 201.1.1 or 611.7.1.2 201.1.2. as appropriate for

the existing construction. 8d nails shall be a minimum of 0.141 inch in

diameter and shall be a minimum of 2-1/4 inch long to qualify for the

provisions of this section for existing nails regardless of head shape or head

diameter.

Board roof

decking secured with at least two 8d nails into roof framing members shall be

deemed to be sufficiently connected.

Board roof decking secured with smaller fasteners than 8d nails or with

fewer than two 8d nails per board shall be deemed sufficiently connected if two

8d clipped head, round head, or ring shank nails are in place on each framing

member.

611.7.1.1 201.1.1 Roof decking consisting of sawn

lumber or wood planks up to 12” wide and secured with at least two nails

(minimum size 8d) to each roof framing member it crosses shall be deemed to be

sufficiently connected. Sawn lumber or

wood plank decking secured with smaller

fasteners than 8d nails or with fewer than two nails (minimum size 8d) to each

framing member it crosses shall be deemed sufficiently connected if fasteners

are added such that two clipped head, round head, or ring shank nails (minimum

size 8d) are in place on each framing member it crosses.

611.7.1.2 201.1.2 For roof decking consisting of wood

structural panels, fasteners and spacing required in columns 3 and 4 of Table 611.7.1.2

201.1.2 are deemed to comply with the requirements of Section 606.3 507.2.2,

507.2.2,

Supplemental fasteners as required by Table 611.7.1.2 201.1.2 shall be 8d ring shank nails

with round heads and the following minimum dimensions:

1. 0.113-inch nominal shank diameter

2. Ring diameter a minimum of 0.012-inch greater than over shank diameter

3. 16 to 20 rings per inch

4. a minimum 0.280-inch full

round head diameter

5. Ring shank to extend a minimum of 1 ½” from the tip of the nail.

6. Minimum 2-1/4 inch

nail length

Table 611.7.1.2 201.1

Supplement Fasteners at Panel Edges and Intermediate

Framing

|

Existing fasteners |

Existing spacing |

Wind speed 110 mph or less supplemental fastener

spacing shall be no greater than |

Wind speed greater than 110 mph supplemental

fastener spacing shall be no greater than |

|

Staples or 6d |

Any |

6” o.c. b |

6” o.c. b |

|

8d clipped head, round

head, smooth or ring shank |

6” o.c. or less |

None necessary |

None necessary |

|

8d clipped head |

Greater than 6” o.c. |

6” o.c.a |

6” o.c. |

|

|

|

|

|

a. Maximum spacing determined based on existing

fasteners and supplemental fasteners.

b. Maximum spacing determined based on

supplemental fasteners only.

611.7.2 201.2

Roof secondary water barrier for site-built single family residential

structures. A secondary water barrier shall be installed

using one of the following methods when roof covering is removed and

replaced: roofing replacement when reroofing.

a) All joints in structural panel roof

sheathing or decking shall be covered with a minimum 4 in. wide strip of

self-adhering polymer modified bitumen tape applied directly to the sheathing

or decking. The deck and self adhering

polymer modified bitumen tape shall be covered with one of the underlayment

systems approved for the particular roof covering to be applied to the

roof.

b) Outside the High

Velocity Hurricane Zone, tThe entire roof deck shall be

covered with an approved self-adhering polymer modified bitumen cap

sheet meeting ASTM D 1970 or an approved

self-adhereing synthetic underlaymet installed in accordance with the

manufacturer’s installation instructions. No additional underlayment shall be required

on top of this cap sheet for new installations.

c) In the HVHZ, the entire roof deck shall be

covered with an approved asphalt impregnated 30#

felt underlayment installed with nails and tin-tabs as required for the HVHZ in accordance with Sections 1518.4 of the Florida Building Code, Building or

R4402.7.2, R4402.7.3, or R4402.7.4 of the Florida Building Code, Residential. This method

shall also be acceptable

in the non-HVHZ regions of

d) In regions of Outside of the HVHZ, an

underlayment system approved for the particular roof

covering shall be applied with the following modification:

(1) For roof slopes that require one layer

of underlayment, complying with section 1507.2.3 of the Florida Building Code,

Building fastened as described below or a layer of approved asphalt impregnated approved ASTM D 226 Type I or Type II (#30) felt underlayment

or approved synthetic underlayment shall be installed. The felt or

synthetic underlayment is to be fastened with 1” round plastic cap or metal

cap nails, attached to a nailable deck in a grid pattern of 12 inches (305 mm)

staggered between the overlaps, with 6-inch (152 mm) spacing at the

overlaps. The

synthetic underlayment shall be fastened in accordance with the manufacturer’s

recommendations.

(2) For roof

slopes that require two layers of underlayment, an

approved asphalt impregnated ASTM D 226 Type I or Type II (#30)

underlayment of 2:12 to 4:12 an additional layer of felt shall

be installed in a shingle-fashion and lapped 19” and fastened as described

above. An approved synthetic underlayment shall be installed in accordance with

the manufacturer’s installation instruction. (No additional underlayment shall be required over the top of this

sheet).

e)

Application of a two-part urethane based closed cell spray-on adhesive to the

attic side of the joints between the sheathing and along both sides of the

truss top chords or rafters shall be deemed to meet the requirements for

the secondary water barrier.

Exceptions:

1. Roof slopes < 2:12 having a continuous roof system shall be deemed

to comply with section 201.2 requirements for a secondary water barrier.

2. Clay and Concrete tile roof systems installed as required by the

Exceptions:

1. Roof slopes < 2:12 having a continuous roof system shall be deemed

to comply with section 611.7.2 201.2 requirements for a secondary water

barrier.

2. Clay and Concrete tile roof systems installed as required by the 201.2 for

Secondary Water Barriers.

1. An asphalt impregnated 30# felt underlayment

installed with nails and tin-tabs as required for the HVHZ and covered with

either an approved self-adhering polymer modified bitumen cap sheet or an

approved cap sheet applied using an approved hot-mop application shall be

deemed to meet the requirements for the secondary water barrier.

611.8 101.2 When a roof covering

on an existing site-built-single-family residential structure is removed and replaced on a building that is located

in the wind-borne debris region as defined in s. 1609.2 of the

(a) Roof to wall

connections shall be improved as required by Section 611.8.1 201.3.

(b) Mandated retrofits of the roof-to-wall

connection shall not be required beyond a 15 percent increase in the cost of

re-roofing.

(c) Where

complete retrofits of all the roof-to-wall connections as prescribed in Section

611.8.1 201.3 would exceed 15 percent of the cost of the

re-roofing project, the priorities outlined in Section 611.8.1.7 201.3.75

shall be used to limit the scope of work to the 15 percent limit.

Exception: Single family

residential structures permitted subject to the Rule section.

201.3 611.8.1 Roof-to-wall

connections for site-built

single family residential structures. Where

required by Section 611.8 101.2, the intersection of roof framing

with the wall below shall be strengthened by adding metal connectors, clips,

straps, and fasteners such that the performance level equals or exceeds the

uplift capacities as provide sufficient resistance to meet the uplift

loads specified in Table 611.8.1 201.3 either because of

existing conditions or through retrofit measures. As an alternative to an

engineered design, the prescriptive retrofit solutions provided in Sections 611.8.1.1

201.3.12 through 611.8.1.6 201.3.45 shall be

accepted as meeting the mandated roof-to-wall retrofit requirements.

Exceptions:

1. Where it can be demonstrated

(by code adoption date documentation and permit issuance date) that

roof-to-wall connections and/or roof-to-foundation continuous load path

requirements were required at the time of original construction.

2. Roof- to- wall

connections shall not be required unless evaluation and installation of

connections at gable ends or all corners can be completed for 15% of the cost

of roof replacement.

611.8.1.1 201.3.1 Access for

Retrofitting Roof to Wall Connections. These provisions are not intended to limit

the means for gaining access to the structural elements of the roof and wall

for the purposes of retrofitting the connection. The retrofit of roof to wall connections can be made by access through

the area under the eave, from above through the roof, or from the interior of

the house. Methods for above access

include removal of roof panels or sections thereof or removal of portions of

roof paneling at selected locations large enough for access, viewing, and installing

the retrofit connectors and fasteners.

Where panels or

sections are removed, the removed portions shall not be reused. New paneling shall be used and fastened as in

new construction.

Holes shall be deemed adequately repaired if a patch of

paneling is installed with no gap greater than ½ inch between the patch and the

existing sheathing and if the patch is supported using one of the following

methods.

a) Solid 1-1/2 inch lumber

shall fully support the patch and shall be secured to the existing sheathing

with #8 by 1-1/4 inch screws spaced a minimum of 3” around the perimeter with

screws a minimum of ¾ inch from the near edge of the hole. The patch shall be secured to the lumber with

#8 x 1-1/4 inch screws spaced on a grid no greater than 6 inches by 6 inches

with no fewer than 2 screws.

b) Holes that extend

horizontally from roof framing member to adjacent roofing framing member that

are less than or equal to 7” wide along the slope of the roof shall be supported by minimum of 2x4 lumber

whose face is attached to each roofing framing members using a minimum of 2

each 3-inch long fasteners (#8 screws or

10d common nails) connecting the two.

The patch shall have attached to its bottom running horizontally a

minimum 2x4 either flat wise or on edge secured with #8 x 1-1/4 inch screws a

maximum of 4 inches on center and no more distant from the end of the added

lumber than 3 inches. The patch shall be

secured with two #8 x 1-1/4 inch screws to each support member.

611.8.1.2

201.3.2 Partially inaccessible straps: Where part of a strap is inaccessible, if

the portion of the strap that is observed is fastened in compliance with these

requirements, the inaccessible portion of the strap shall be presumed to comply

with these requirements.

611.8.1.3

201.3.31 Prescriptive method for gable roofs on a wood

frame wall. Sufficient eave sheathing shall be removed to

expose a minimum of 6-feet of framing members, measured from the corner, along

the exterior wall on each side of each gable end. The

anchorage of each of the exposed rafters or truss within 6 ft of the

framing members as measured from the corner along the exterior wall on

each side of each gable end shall

be inspected. Wherever a strap is

missing or an existing strap has fewer than four fasteners on each end,

approved straps, ties or right angle gusset brackets with a minimum

uplift capacity of 500 lbs shall be installed that connect each rafter or truss

to the top plate below. Adding fasteners

to existing straps shall be allowed in lieu of adding a new strap provided the

strap is manufactured to accommodate at least 4 fasteners at each end. Wherever access makes it possible (without

damage of the wall or soffit finishes), both top plate members shall be

connected to the stud below using a stud to plate connector with a minimum

uplift capacity of 500 lbs. Use of

straps that connect directly from the rafter or truss to the wall stud below

shall be allowed as an alternate provided the two members align with no more

than 1-1/2” offset.

611.8.1.4

201.3.42 Prescriptive method for gable roofs on a

masonry wall. Sufficient eave sheathing shall be removed to

expose a minimum of 6-feet of framing members, measured from the corner, along

the exterior wall on each side of each gable end. The anchorage of each of the exposed

rafters or truss within 6 ft of the framing members as

measured from the corner along the exterior wall on each side of each

gable end shall be inspected. Wherever a strap is missing or an existing

strap has fewer than four fasteners on each end, approved straps, ties or right

angle gusset brackets with a minimum uplift capacity of 500 lbs shall be

installed that connect each rafter or truss to the top plate below or directly

to the masonry wall using approved masonry screws that will provide at least a

2-1/2 embedment into the concrete or masonry.

When the straps or right angle gusset brackets are attached to a wood

sill plate, the sill plate shall be anchored to the concrete masonry wall

below. This anchorage shall be accomplished

by installing ¼-inch diameter masonry screws, each with supplementary ¼-inch

washer, having sufficient length to develop a 2-1/2 inch embedment into the

concrete and masonry. These screws shall

be installed within 4-inches of the truss or rafter on both sides of each

interior rafter or truss and on the accessible wall side of the gable end truss

or rafter.

611.8.1.5

201.3.53

Prescriptive method for hip roofs on a wood frame wall. Unless it is possible to verify through

non-destructive inspection or from plans prepared by a design professional that

the roof structure is anchored at least as well as outlined below, access

shall be provided at a minimum to the hip rafter (commonly known as a “king

jack”), to the hip girder and at each corner of the hip roof. The hip rafter (commonly known as a “king jack”), the hip girder and

the rafters/trusses adjacent to the hip girder Sufficient

corner eave sheathing shall be removed from the side of the hip ridge parallel

to the roof ridge to provide access to a minimum 6-foot length of the exterior

wall. The hip ridge board and any

exposed rafters that are not anchored with a strap having at least four

fasteners on each end, shall be connected to the top plate below using a strap

or a right angle gusset bracket having a minimum uplift capacity of 500

lbs. Adding fasteners to existing straps

shall be allowed in lieu of adding a new strap provided the strap is

manufactured to accommodate at least 4 fasteners at each end. Wherever access makes it possible (without

damage of the wall or soffit finishes), both top plate members shall be

connected to the stud below using a stud to plate connector with a minimum

uplift capacity of 500 lbs. Use of

straps that connect directly from the hip rafter, hip girder or adjacent

rafters/trusses to the wall stud below shall be allowed as an alternate

provided the two members align with no more than 1-1/2” offset.

611.8.1.6

201.3.64 Prescriptive method for hip roofs on a masonry

wall. Unless it is possible to verify through

non-destructive inspection or from plans prepared by a design professional that

the roof structure is anchored at least as well as outlined below, access

shall be provided at a minimum to the hip rafter (commonly known as a “king

jack”), to the hip girder and at each corner of the hip roof. The hip rafter (commonly known as a “king jack”), the hip girder and the rafters/trusses adjacent to the hip

girder Sufficient corner eave sheathing shall be

removed from the side of the hip ridge parallel to the roof ridge to provide

access to a minimum 6-foot length of the exterior wall. The hip ridge board and any exposed rafters

that are not anchored with a strap

having at least four fasteners on each end, shall be connected to the concrete

masonry wall below using approved straps or right angle gusset brackets with a

minimum uplift capacity of 500 lbs.

Adding fasteners to existing straps shall be allowed in lieu of adding a

new strap provided the strap is manufactured to accommodate at least 4

fasteners at each end. The straps or

right angle gusset brackets shall be installed such that they connect each

rafter or truss to the top plate below or directly to the masonry wall using

approved masonry screws that will provide at least a 2-1/2 embedment into the

concrete or masonry. When the straps or

right angle gusset brackets are attached to a wood sill plate, the sill plate

shall be anchored to the concrete masonry wall below. This anchorage shall be accomplished by

installing ¼-inch diameter masonry screws, each with supplementary ¼-inch

washer, with sufficient length to develop a 2-1/2 inch embedment into the

concrete and masonry. These screws shall

be installed within 4-inches of the truss or rafter on both sides of each

interior rafter or truss and on the accessible wall side of the gable end truss

or rafter.

611.8.1.7

201.3.65 Priorities for mandated roof-to-wall retrofit

expenditures. Priority shall be given to

connecting the exterior corners of roofs to walls where the spans of the

roofing members are greatest. For houses with both hip and gable roof ends,

the priority shall be to retrofit the gable end roof-to-wall connections unless

the width of the hip end is more than 1.5 times greater than the width of the

gable end. Priority shall be given to connecting the

corners of roofs to walls below where the spans of the roofing members are

greatest.

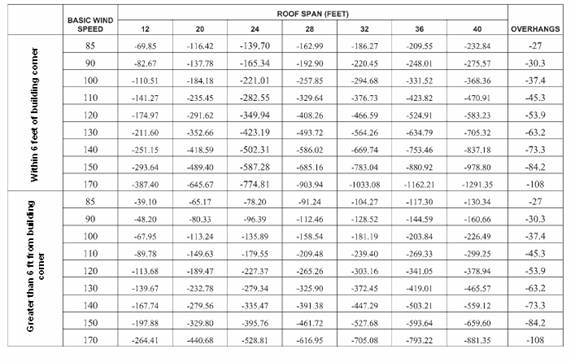

Table 611.8.1 201.3

Required

Uplift Capacities for Roof-to-Wall Connections

(POUNDS

PER LINEAR FOOT)

Chapter 1,

Administration

101.3 105.15 When any activity

requiring a building permit that is applied for on or after s. 1609.2 of the , Building and that has

an insured value of $750,000 or more, or, if the building is uninsured or for

which documentation of insured value is not presented, has a just valuation for

the structure for purposes of ad valorem taxation of $750,000 or more.

Opening protections as required within the

[ Appendix A Gable and Wall

Bracing Retrofit has been omitted and will be provided later

The Committee at

the last meeting deferred action for Richard Reynolds to provide language

necessary to incorporate the appendix as a Chapter in the Existing Building

Volume.]